(Teeth Profile, Material, Bore Size)

Selecting the right timing pulley is critical for efficient power transmission in machinery, robotics, and industrial applications. A poorly chosen pulley can lead to premature belt wear, misalignment, and system failure.

This guide covers:

✔ Timing pulley teeth profiles (MXL, XL, L, HTD, GT2, etc.)

✔ Material selection (Aluminum vs. Steel)

✔ Bore size & customization

✔ FAQs for common challenges

1. Understanding Timing Pulley Teeth Profiles

The tooth profile determines how the belt engages with the pulley. Choosing the wrong profile causes skipping, noise, and reduced efficiency.

| Profile | Pitch (mm/inch) | Best For |

| MXL | 0.080″ (2.032mm) | Light-duty (3D printers, small robotics) |

| XL | 0.200″ (5.08mm) | Conveyors, packaging machines |

| L | 0.375″ (9.525mm) | Industrial automation, CNC routers |

| HTD | 3mm, 5mm, 8mm | High-torque (Industrial robots, heavy machinery) |

| GT2/GT3 | 2mm, 3mm | Precision (3D printers, linear motion systems) |

Pro Tip:

- HTD & GT2/GT3 handle higher loads with minimal backlash.

- MXL/XL are cost-effective but not suited for heavy-duty use.

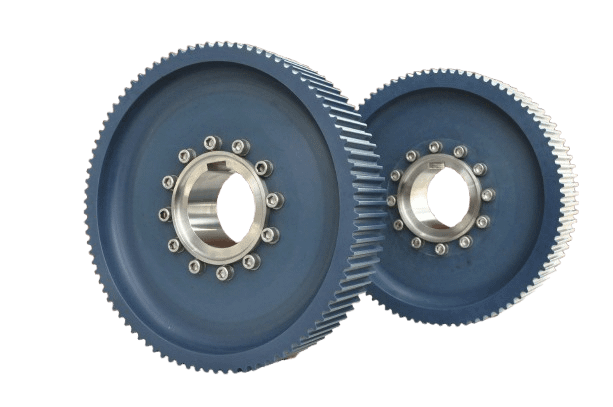

2. Timing Pulley Material Selection

The material affects durability, weight, and corrosion resistance.

Aluminum Timing Pulleys

✔ Lightweight (Ideal for high-speed applications)

✔ Corrosion-resistant (Anodized finish available)

✔ Cost-effective for general-purpose use

Best for: 3D printers, robotics, light machinery

Steel Timing Pulleys

✔ Extreme durability (Handles heavy loads)

✔ Higher temperature resistance

✔ Longer lifespan in abrasive environments

Best for: Mining equipment, automotive systems, industrial presses

Pro Tip:

- Stainless steel is best for food processing & marine applications (rust-proof).

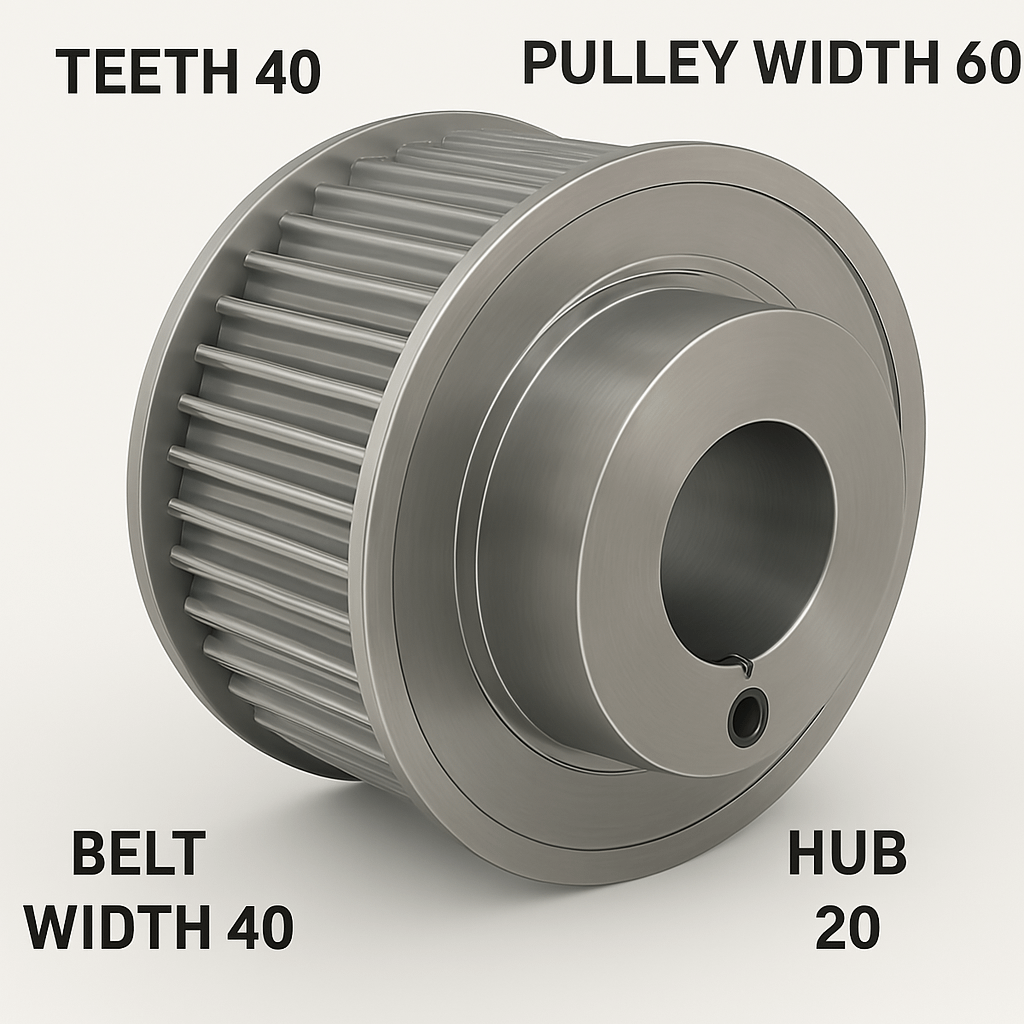

3. Bore Size & Customization

The bore size (inner diameter) must match your shaft diameter.

Standard Bore Sizes

- Metric: 5mm, 8mm, 10mm, 12mm

- Imperial: 1/4″, 3/8″, 1/2″, 3/4″

Custom Bore Options

- Key ways & Set Screws (Prevent slippage)

- Tapered Bores (For specialized machinery)

- Flanged Designs (For belt retention)

Pro Tip:

- Always measure your shaft with calipers for precision.

- For high-torque applications, use keyed bores instead of set screws.

4. How to Match a Timing Pulley to Your Belt

- Check Belt Specifications (Teeth profile, pitch, width)

- Confirm Pulley Teeth Count (Affects speed ratio)

- Ensure Proper Tension (Too tight = premature wear | Too loose = slippage)

Formula for Speed Ratio:

Driver Pulley Teeth ÷ Driven Pulley Teeth = Speed Ratio

5. Common Timing Pulley Mistakes to Avoid

❌ Mismatched Tooth Profile (Causes belt jumping)

❌ Incorrect Bore Size (Leads to shaft damage)

❌ Using Aluminum in High-Temp Environments (Can deform)

❌ Ignoring Maintenance (Lack of lubrication increases wear)

FAQs: Timing Pulley Selection

Q1: How do I know which tooth profile to choose?

A: Match it to your belt type (check manufacturer specs). For high-load applications, HTD or GT3 profiles are best.

Q2: Can I use an aluminum pulley for heavy machinery?

A: Only if loads are minimal. For industrial use, steel pulleys are recommended.

Q3: What’s the difference between GT2 and GT3 profiles?

A: GT3 has rounded teeth for smoother engagement and less backlash than the GT2.

Q4: How often should I replace my timing pulley?

A: Inspect every 6-12 months for:

- Worn teeth

- Cracks or deformities

- Belt slippage

Q5: Can I get a custom-sized timing pulley?

A: Yes! We manufacture custom bores, teeth counts, and materials – Contact Us for specs.

Conclusion: Key Takeaways

- Tooth Profile → Match to belt type (HTD/GT3 for heavy loads).

- Material → Aluminum (lightweight) or Steel (durability).

- Bore Size → Must fit shaft precisely (key ways for high torque).

Need Expert Help?

Get a Free Timing Pulley Consultation